Abnormally high room temperature and high-temperature tensile properties were observed in Inconel 718 with direct aging line arc-directed energy deposition.

If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

It is known that chromium nickel-iron alloy (IN) 718 processed by line arc directed energy deposition (DED) exhibits rough columnar grains, strong texture, and significant chemical and microstructural heterogeneity under manufacturing conditions. Homogenization treatment is usually carried out before aging to eliminate unevenness and harmful precipitation for better mechanical properties. However, in this study, direct aging (DA) at 700 ° C without homogenization resulted in room temperature yield strength, ultimate tensile strength (UTS), and elongation comparable to forging conditions. It was one of the highest properties reported by line arc DED IN718.

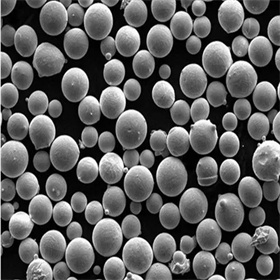

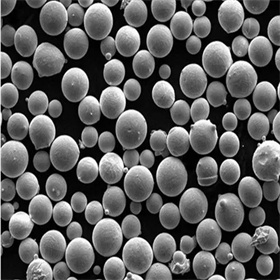

(Inconel 718)

Under aging at 650 to 750 ° C, DA samples exhibit significant ductility when deformed at high temperatures. In addition, when aged below 750 ° C, the UTS of DA IN718 is significantly higher than that of homogenization treatment. These superior mechanical properties are likely due to uneven and layered precipitation, including disc-shaped core areas with diam ranging from a few to tens of nanometers γ And the micron level Laves phase and carbides in the interdendritic region.

Trunnano 3D Printing Nickel Alloy IN718 Powder

Inconel 718, or N07718, is a nickel iron-based superalloy with excellent high-temperature strength, oxidation, and corrosion resistance. This alloy is widely used in various high-tech fields, including but not limited to the following aspects:

Aerospace field

Inconel 718 is widely used to manufacture aircraft engines and aerospace components, such as turbine blades, jet tubes, etc. Its excellent high-temperature oxidation and corrosion resistance make it an ideal choice for withstand extreme temperatures and pressures.

Energy sector

Inconel 718 is used in the petroleum, natural gas, chemical, and nuclear industries, particularly in the nuclear energy sector, to manufacture reactors' internal structure and functional components.

Medical field

Inconel 718 is also widely used in medical devices, such as artificial joints, bone nails, etc., due to its fantastic biocompatibility and corrosion resistance.

(Inconel 718)

Automobile manufacturing

Inconel 718 is used in key components of automobiles, such as high-performance engines, exhaust systems, and brake systems, to improve vehicle performance and safety.

Other fields

Inconel 718 is also used to manufacture key components in marine engineering, chemical, and power industries.

High-quality inconel 718 powder supplier

TRUNNANO is a trusted global supplier and manufacturer of chemical materials with over 12 years of experience in ultra-high quality nanomaterials and chemicals. The company has developed several powder materials and chemicals. Provide OEM service. If you are looking for inconel 718 powder, please get in touch with us. You can click on the product to contact us.

Inquiry us