Properties and Applications of Ti6Al4V TC4 Powder

From April the French government will reduce fuel taxes slightly to ease the burden on consumers.

Warned of possible energy shortages in France by the end of the year and called on the French to conserve electricity and gas from now on, saying that if nothing was done, The energy situation will be tough this winter. Some experts say that there are two main reasons for France's energy crisis: first, the conflict between Russia and Ukraine affected the gas market and caused supply tension; The second is a safety review of France's newest nuclear power plant, which may lead to a reduction in output this year. In order to alleviate the energy crisis, the whole French society needs to be mobilized, whether it is the industrial sector, the tertiary sector or every French citizen. Now it is urgent. Rising fuel prices may also have an impact on shipments of the TC4.

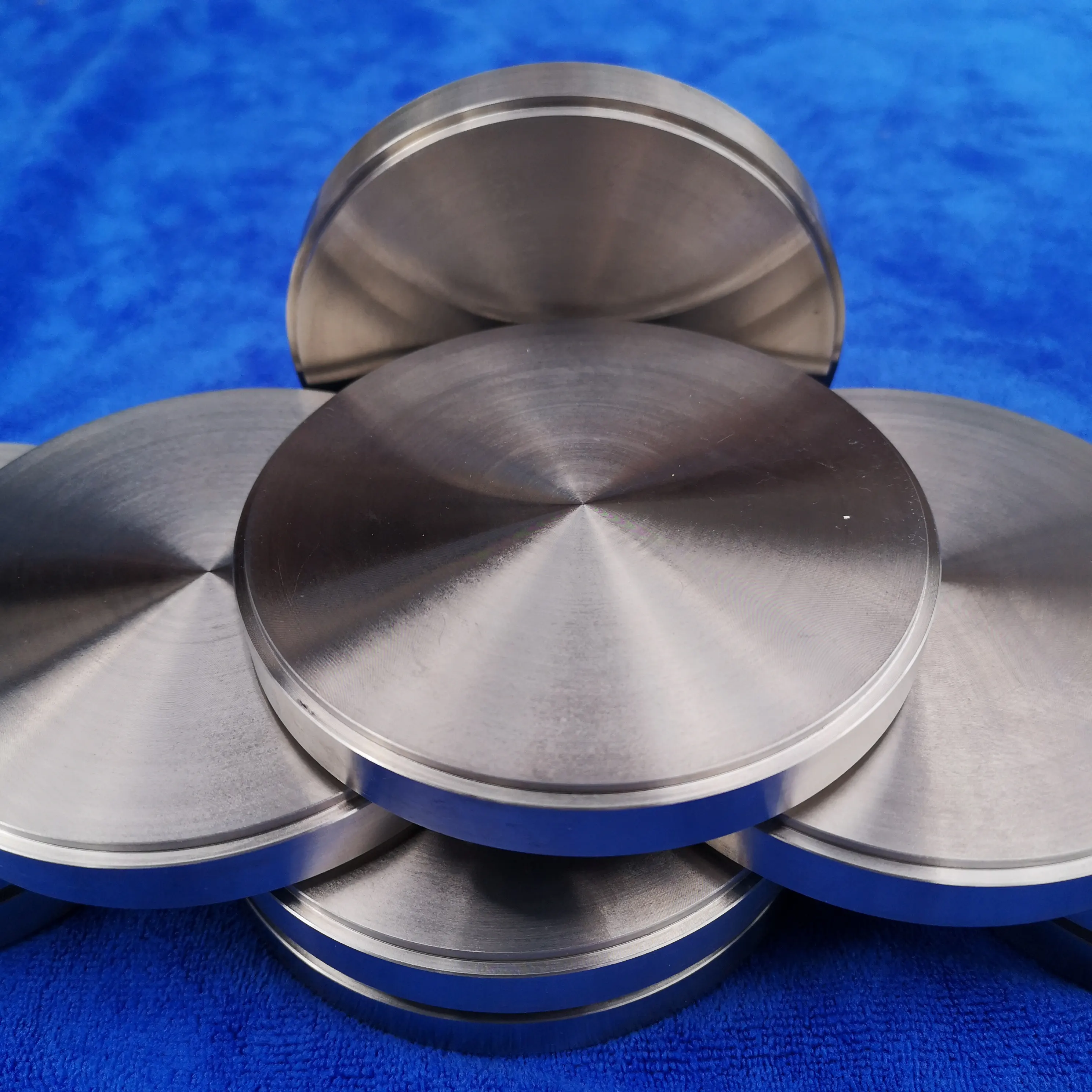

Introduction to Ti6Al4V Powder TC4 Powder

TC4 titanium alloy material, also known as Ti-6Al-4V titanium alloy, belongs to the (α+β) type titanium alloy. It has good comprehensive mechanical properties, good stability of the structure, good toughness, plasticity, and high-temperature deformation performance. It can be better for hot pressure processing, quenching, and aging to strengthen the alloy. The strength after heat treatment is about 50%~100% higher than that after annealing. It has high strength at high temperatures and can work at 400℃~500℃ temperature for a long time.

TC4 also has good low-temperature performance. It still has good toughness below -196℃and, therefore, is used to manufacture low-temperature high-pressure vessels, such as liquid hydrogen fuel tanks for rockets and missiles.

Physicochemical Properties of Ti6Al4V Powder TC4 Powder

TC4 titanium alloy material is characterized by lightweight, excellent mechanical properties, corrosion resistance, and biocompatibility. In addition, it has low thermal conductivity and is non-magnetic.

Titanium-based metal, as a new type of metal, its properties depend on other elements like carbon, nitrogen, hydrogen, oxygen, etc. In general, it has:

1, high strength. Titanium typically has a density of 4.51 grams per cubic centimeter, only 60 percent of that of steel. The density of pure titanium is similar to that of ordinary steel, and the strength of some high-strength titanium alloys is higher than that of many alloy structural steel. Therefore, the specific strength (strength/density) of titanium alloy is much higher than that of other metallic structural materials.

2, high thermal strength. At medium temperature, titanium alloy can still maintain the required strength and can work at 450~500℃ for a long time.

3, good corrosion resistance. Titanium alloy works in a humid atmosphere and seawater medium, its corrosion resistance is far better than stainless steel pitting corrosion, acid corrosion, stress corrosion especially strong alkali, chloride, chlorine organic matter, nitric acid, sulfuric acid, and so on.

4, good low-temperature performance. Titanium alloys can still maintain mechanical properties at low and ultra-low temperatures. TA7 is a titanium alloy with good low-temperature performance and very low gap elements, which can maintain certain plasticity at -253℃. Therefore, titanium alloy is also an important low-temperature structural material.

5, high chemical activity. Titanium has high chemical activity and has a strong chemical reaction with oxygen, nitrogen, hydrogen, CO, CO2, water vapor, ammonia, and so on in the atmosphere. When the carbon content is greater than 0.2%, hard TiC is formed in titanium, and a hard TiN surface is formed at high temperatures. When the carbon content is above 600℃, titanium can absorb oxygen and form a hard hardening layer. At high temperatures, with the increase of hydrogen content, a hard hardening layer is formed. After inhalation, the depth of the hard brittle surface can reach 0.1~0.15mm, and the hard brittle surface can reach 20%~30%. Its chemical affinity is also strong, and easy to adhere to the friction surface.

6, small thermal conductivity elasticity. The thermal conductivity of the titanium system is about 1/4 of nickel, 1/5 of iron, 1/14 of aluminum, and the thermal conductivity of various titanium alloys is about 50%. The elastic modulus of titanium is about 1/2 that of steel, with poor stiffness and easy deformation. It is not suitable for slender rods and thin-walled parts.

| Ti6Al4V Powder TC4 Powder Properties | |

| Other Names | Ti6Al4V Powder, TC4 Powder |

| CAS No. | N/A |

| Compound Formula | TA0,TA1,TC4,TC4 ELI,TC11,TC17,TC18,TC21,TA7,TA12,TA15,TA17,TA19, Ti40,Ti60,TiAl(Ti36Al,Ti48Al2Cr2Nb) |

| Molecular Weight | N/A |

| Appearance | grey powder |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | N/A |

| Solubility in H2O | N/A |

| Exact Mass | N/A |

3D Printing Ti6Al4V Powder TC4 Powder

Applications of Ti6Al4V Powder TC4 Powder

Ti6Al4V is used in many high-performance engineering applications, such as aerospace, automotive, and medical device manufacturing.

Aerospace: Components for jet engines

Manufacturing: Industrial turbines

Car: muffler

Medical: implants, artificial bones

In the petrochemical industry: In most inorganic salts, TC4 titanium rods are completely inert and have excellent corrosion resistance. For example, in the production of electrolytic Mn02, the electrolyte is a neutral MnSO4 solution, which requires the electrode to be resistant to sulfate corrosion. The effect of a telegraph machine made of lead alloy and graphite is not good. After switching to titanium, the anode is not corroded and becomes a semi-permanent device.

TC4 titanium alloy rod has excellent corrosion resistance in almost all organic acids and organic media except formic acid and oxalic acid. In addition to methanol, titanium also resists corrosion by organic alcohols, aldehydes, and ketones.

For example, in the petrochemical industry, acetic acid is prepared from acetaldehyde. Because acetic acid, acetaldehyde, chloride, and catalyst corrode the stainless steel equipment seriously, titanium material is used to solve the corrosion problem of equipment in acetic acid production. Acetone, for example, can be made from propylene, or titanium production facilities can be used. Japan built a plant with an annual output of 30,000 tons of acetone and used nearly 40 tons of titanium.

Finally, TC4 titanium rods are resistant to wet H2S gas, wet SO4 gas, ammonia, and industrial atmospheres (titanium should be used with particular care in small hydrogen-containing media and pure oxygen).

For example, in the oil refining industry, equipment is often corroded by H2S, NH8, sulfide, chloride, and titanium equipment can solve the corrosion problem. Titanium is mainly used in distillation towers, condensers, air coolers, and other equipment in petroleum refining. Titanium is an ideal corrosion-resistant material in ammonia and urea production.

Main Supplier of Ti6Al4V Powder TC4 Powder

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality chemicals and Nanomaterials, including silicon powder, nitride powder, graphite powder, zinc sulfide, calcium nitride, 3D printing powder, etc.

If you are looking for high-quality Ti6Al4V Powder TC4 Powder, please feel free to contact us and send an inquiry. ([email protected])

All aspects of human beings are constantly improving, and the demand for TC4 is also increasing.If you are engaged in the TC4 industry, you just happen to contact us.

Inquiry us

PREVIOUS NEWS